The name “Multi-Vari” was given to this form of analysis by L.A. Seder in his classic paper “Diagnosis with Diagrams,” which appeared in Industrial Quality Control in January and March 1950. The premise is to utilize graphics to understand where the variation in a process exists. Is it excessive variation within a single piece, excessive variation from piece to piece, or is the variation excessive from time to time. If we are relating this to service delivery substitute “service delivery to customers”, “service delivery from customer to customer”, and “service delivery from time to time” in the previous sentence.

Multi-Vari Studies are often classified as either a “Nested Design” or a “Crossed Design.” In the Nested Design the data is collected without making changes to the process to investigate where the variation is coming from. It could be positional which is within piece variation, it could be cyclical which is consecutive piece-to-piece variation, or it could be temporal which is time-to-time variation such as day-to-day, or week-to-week. The following graphic is an example where we are trying to find the source of process variation with regard to warp in a glass container.

From this Nested Design Multi-Vari Chart we can clearly see that Machine Section 7 is very different than any other section on the machine. Section 7 becomes the target for variation reduction. The question becomes, “Why is it so different than the rest of the machine?”

In the Crossed Design the plan is to test changes to the process in a balanced manner following an on or off strategy. In the Crossed Design either 2 or 3 potential variation contributor process variables are studied at 2 different settings. Analysis of Variance is often added as part of the study to provide detailed statistics that support what the graphic analysis portrays. The ANOVA provides the verdict of “guilty beyond a shadow of a doubt” to support what we see graphically. The following graphic is an example where we are trying to minimize the time it takes to boil a cup of water in a microwave oven.

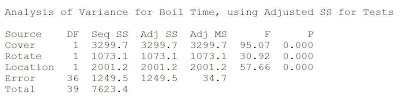

From this Crossed Design Multi-Vari Chart it is clear that to minimize the time to boil a cup of water in a microwave oven the container should be rotated, located 4 inches off center, and covered. To add further proof to this graphic finding an ANOVA (analysis of variance) was conducted with the following results.

The sources of variation are Cover, Rotate, and Location. Each are significant with p values that are less than .0009 (assume worst case for unknown digit of 9) which equates to a confidence level of at least of 99.91%.

Multi-Vari Studies provide a graphic means to quickly find 85% of the variation in a product or service. I think you will find this technique to be useful.

No comments:

Post a Comment

Post your comments here. Thank You!